Excavator Based Attachments

Excavator based attachments

There are numerous benefits in using an excavator as the carrier for ground improvement:

- Excavators are less heavy than crawler cranes, needing a less stable work platform.

- Excavators can be faster mobilized. On site assembly is minimal.

- The space on some sites is very limited. Excavators require less space.

- The excavator can push the vibroflot down to achieve faster penetration.

- These advantages make the excavator the preferred carrier rig for many projects.

The maximum depth that can be reached using a 40 ton excavator is for bottom feed stone columns around 8 m and for top feed stone columns 10 m.

Bottom Feed attachment BE4

The BE4 has the following advantages:

- Low capital investment requirement.

- Additional push down force (activation) compared to rope suspended attachments.

- Perfect verticality by design, thanks to optimal control via excavator arm.

- Easy and economical mobilization to site.

- High production rates

- Stable operation, also on not optimal work platforms.

- Quality Control includes: Energy consumption, depth, push down force, verticality, air pressure, and column diameter over depth.

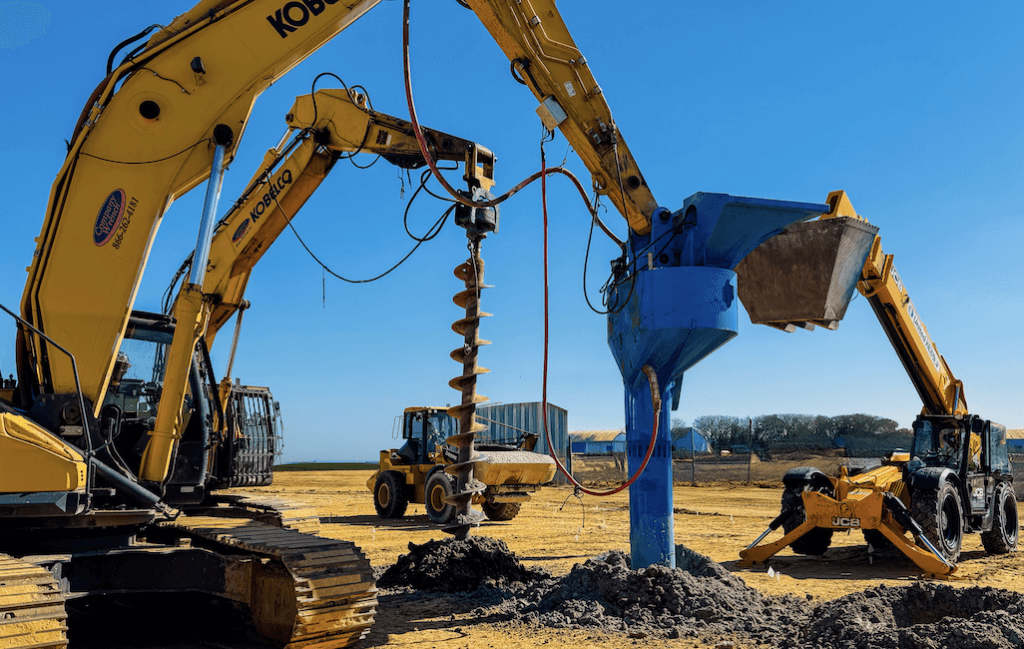

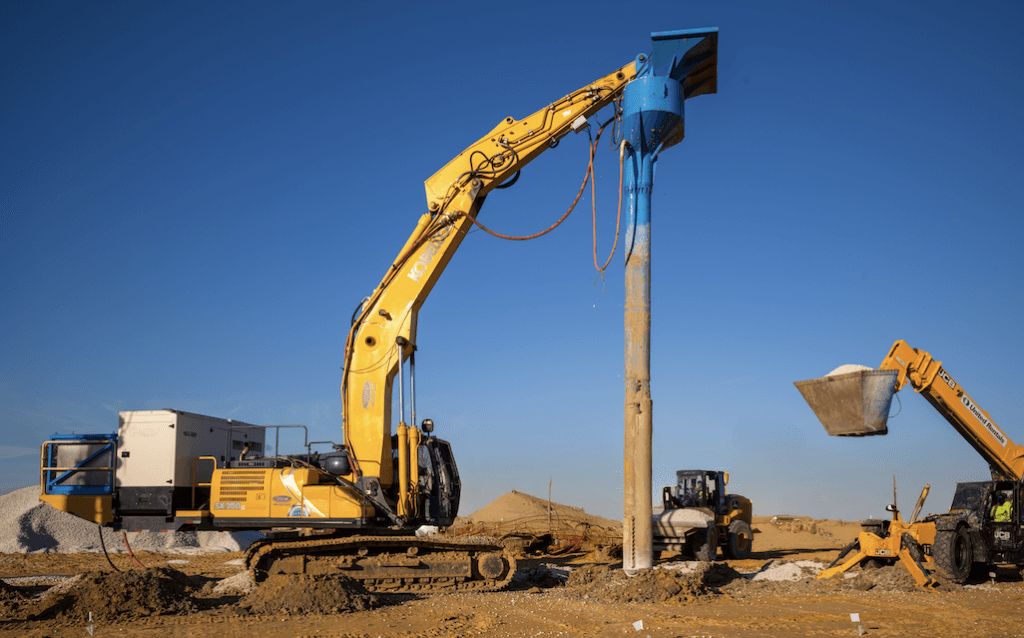

The following shows a BE4 Bottom Feed stone column rig (also called “Vibro Stitcher) operating with a B27 vibroflot in South Carolina, USA.

Movie from site in Austria

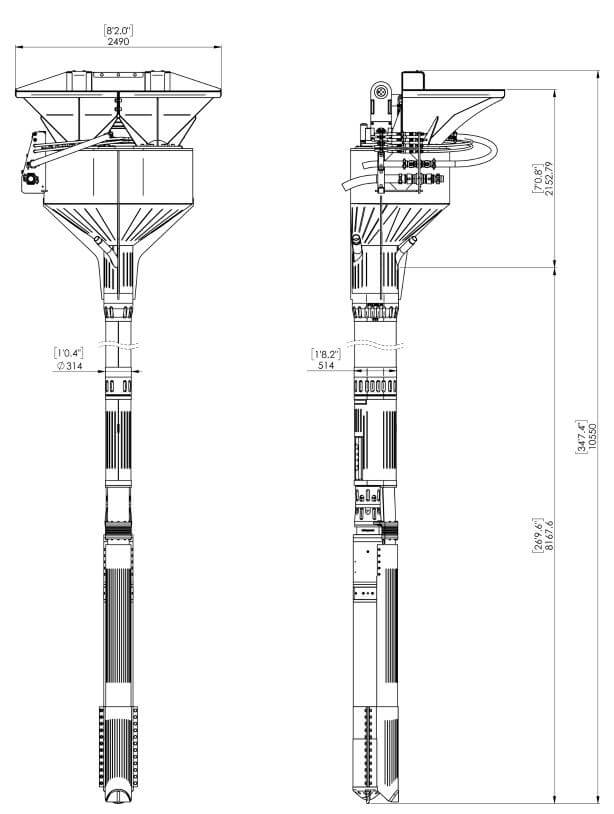

Bottom Feed attachments BR0 and BR1

The BR0 and BR1 are drill rig type carriers built on a patented adaption of an excavator base machine with a custom mast and outrigger support.

SPECIAL FEATURES:

- Four strong outriggers carry the full weight of the carrier, reducing stress on the undercarriage and increasing overall stability.

- Only the mast and its attachment to the excavator body are custom made, the rest is a standard excavator.

- The BR0 main rope is operated winch free in both directions, due to a rope and pulley setup with hydraulic cylinder inside the mast.

- The BR1 main rope is operated by a reversible Zollern winch.

- With a mast extension, the BR1 can install Stone columns up to a length of 17m.

- The gravel bucket is synchronized with the main rope so that gravel can be filled while the vibroflot keeps moving up and down installing columns.

- The electric generator for the vibroflot is mounted on the back to a patented device that allows lowering such generator to ground level for easier service.

Español

Español